Metal manufacturing is a process technology that processes metal materials into items, parts, and components, including large parts such as Bridges and ships, and even subtle components of engines, jewelry, and watches. It is widely used in science, industry, art, handicraft and other different fields.

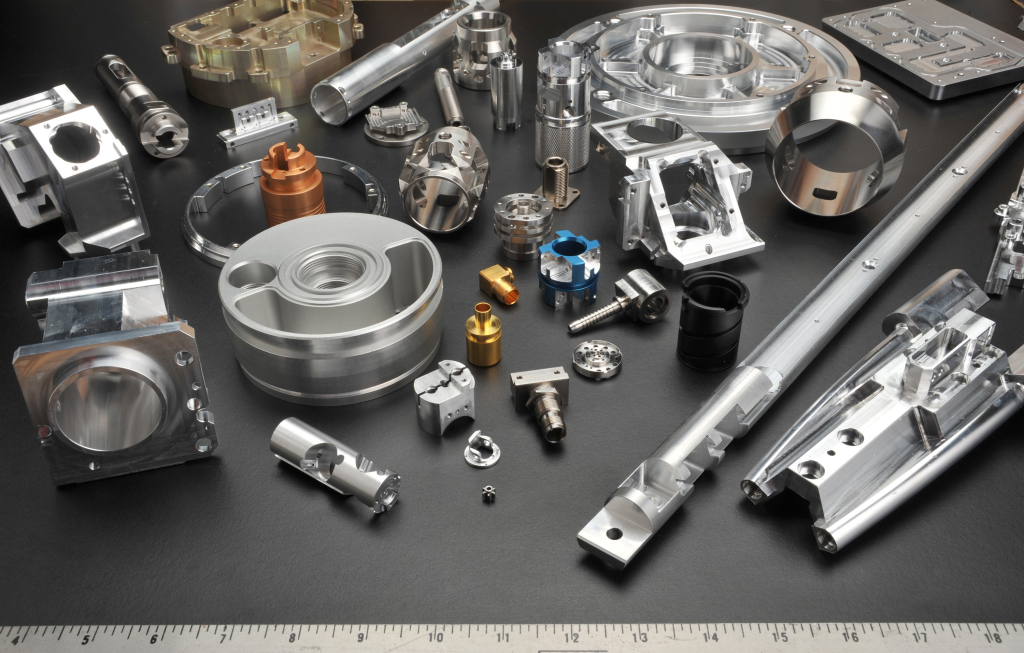

Different Types of Precision Metal Parts

In the world of industrial machines, precision metal parts vary widely in type and function, each serving a critical role in the operation and efficiency of machinery. Common types include:

- Gears: Precision gears are essential in machinery for transmitting torque and motion between machine components. They must be manufactured to exact dimensions to ensure smooth operation and to prevent premature wear or failure.

- Shafts: These are critical for transmitting rotational motion. Precision in their diameter, straightness, and surface finish is crucial for maintaining the alignment and performance of rotating parts.

- Bushings and Bearings: These components help reduce friction between moving parts. Precise manufacturing is essential to ensure they fit perfectly and operate efficiently, minimizing wear and extending the lifespan of machinery.

- Fasteners (bolts, screws, nuts): Fasteners hold various parts of machinery together and must be made to precise specifications to ensure they provide the necessary strength and reliability.

- Pistons and Cylinders: Used in engines and hydraulic systems, these parts must be manufactured with high precision to maintain tight clearances and ensure efficient and leak-free operation.

- Couplings: These connect two shafts together while allowing some degree of misalignment or movement. Precision manufacturing ensures that couplings can transmit torque effectively without causing damage to other components.

- Valves and Nozzles: These regulate the flow of liquids and gases in machinery. Precision is critical in their design to ensure accurate flow rates and to prevent leaks.

- Enclosures and Casings: These protect the internal components of machinery from environmental conditions and human interference. Precision in their design and fabrication ensures proper fit and protection.

- Fixture and Tooling Components: These include jigs, molds, and dies used in the manufacturing process itself. They must be precisely engineered to produce consistent and accurate parts.

- Spindles: These are crucial for the operation of CNC machines, lathes, and milling machines. They must be manufactured to high precision standards to ensure they can hold tools or workpieces securely at high speeds.

- Machine Frames: These provide the structural backbone for various machines. Precision in their fabrication is essential to ensure they can handle mechanical loads and vibrations during operation without failure.

- Weldments: These are complex assemblies created by welding together multiple metal pieces. Each weldment must be precisely engineered to endure specific stresses, making the accuracy of each weld critical for the assembly’s overall structural integrity.

Each of these components plays a vital role in the machinery’s overall function and efficiency, highlighting the importance of precision in metal part manufacturing.

Several Processes of Metal Parts Manufacturing

Die casting

Pressure casting is a metal casting method mainly used to produce complex shaped parts of non-ferrous metals such as aluminum, magnesium, zinc, copper, etc. This method is characterized by the use of high pressure to quickly inject molten metal into a closed mold cavity, and then cooling and curing under high pressure, and finally remove the casting.

The advantage of pressure casting is that it can produce complex shaped parts with high precision, good surface finish and uniform internal quality, and high production efficiency, suitable for mass production. However, the mold cost is high and is not suitable for small batch production.

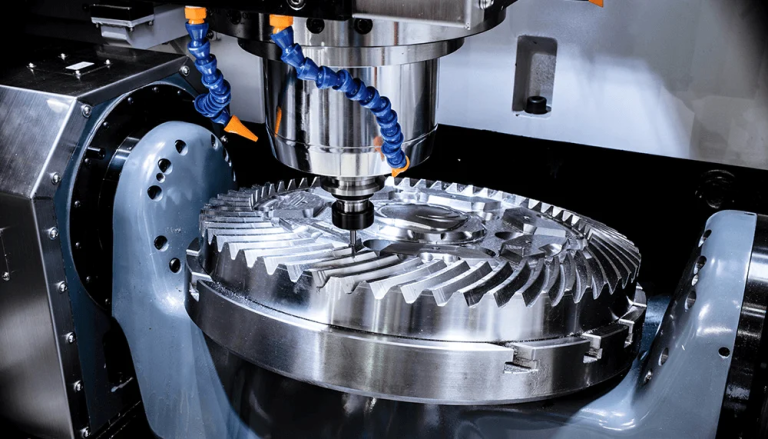

Milling

Milling is a machining method that uses a rotating tool to cut a workpiece. In the milling process, the workpiece is stationary, while the tool rotates and moves, through the cutting movement of the tool and the feed movement of the workpiece, the workpiece is removed and the desired shape and size is formed. The advantage of milling is that it can handle various shapes of workpieces, including complex surfaces and grooves, and it can handle hard materials.

However, the dimensional accuracy and surface quality of milling processing are usually not as good as turning processing.

Turning processing

Turning is a method of cutting the workpiece material by rotating the workpiece and cutting tools to generate the desired shape and dimensions. This is a very common metalworking method that can be used to produce parts of various shapes and sizes.

The advantage of turning is that it can produce parts with high dimensional accuracy and good surface quality, and it can handle a variety of materials, including cemented carbide and non-metallic materials.

Die Forging

Die forging is a metal hot working process, mainly used to manufacture complex shapes and high precision parts. The advantage of die forging is that it can produce parts with complex shapes and high precision, and the material utilization rate is high and the production efficiency is high. However, the manufacturing cost of the mold is high, and it is usually suitable for mass production.

Press

Stamping is a metal processing process in which a metal material is plastic deformed or separated in a mold by applying pressure to obtain a part or semi-finished product of a predetermined shape and size.

The advantage of stamping is that it can produce products with high dimensional accuracy, good surface finish, and high production efficiency, which is suitable for mass production. However, the plastic and toughness requirements of the material are high, and it is not suitable for materials with excessive hardness or poor plasticity.

Forging

Forging is a metalworking process whose main purpose is to change the shape, size and properties of metals through the application of force. Forging can improve the density and structure of the metal, thereby improving its mechanical properties. Forging products are widely used in aviation, automobile, agricultural machinery, petroleum machinery, mining machinery and other fields.

3D Printing

Also known as additive manufacturing (AM), refers to the process used to create three-dimensional objects, in which layers of material are formed under computer control to create objects. Objects can be almost any shape or geometry and are generated using digital model data from 3D models or other electronic data sources. Thus, unlike materials that are removed from inventory during traditional CNC machining, 3D printing or AM builds 3D objects from computer-aided design (CAD) models (STL, STP, STEP, SLDPRT) by adding materials layer by layer.

Explore Cutting-Edge Precision Metal Solutions with TOPFAST CNC

Guangzhou Topfast Technology Co., Ltd is a leading manufacturer specializing in rapid prototyping & on-demand production.

With state-of-the-art machines operated by engineers who are unmatched in skills and experience, we offer CNC machining, injection molding, vacuum casting, die casting,3D printing, sheet metal fabrication, and more.

We are certified in ISO9001, ISO16949, and ISO13485, reflecting our commitment to innovation and improvement.

Our capabilities ensure customers bring ideas to life in no time, providing comprehensive one-stop solutions from prototyping to mass production. Flagship always delivers quality custom parts with precision and efficiency while saving your time, cost, and effort.