If you’re in the market for precision parts—whether for aerospace, medical devices, or everyday equipment—you’ve likely heard of CNC machining. But when it comes to stainless steel, this process becomes even more valuable. Let’s break down what stainless steel CNC machining is, why it matters, and how it can work for your project.

What is Stainless Steel CNC Machining?

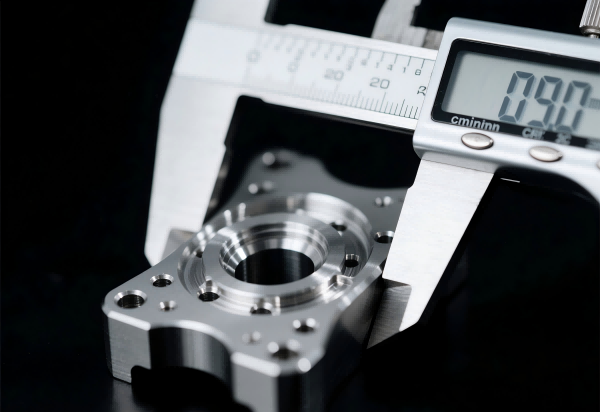

Stainless steel CNC machining is the use of CNC machines to cut, shape, and finish stainless steel parts. This process offers high precision. These machines read digital designs (CAD files) and perform tasks like milling, turning, drilling, and tapping.

Key Capabilities of CNC Machining:

- High dimensional accuracy

- Consistent repeatability

- Complex geometry production

- Custom prototyping to full-scale production

Choosing the Right Stainless Steel Grade

Selecting the optimal grade is critical for performance and manufacturability. Here’s a comparison of common CNC machining grades:

| Stainless Steel Grade | Family | Key Properties | Machinability Rating | Common Applications |

|---|---|---|---|---|

| 303 | Austenitic | Good corrosion resistance, excellent machinability (added sulfur). | Excellent | Shafts, fasteners, fittings, valve components. Ideal for complex, high-volume parts. |

| 304 / 304L | Austenitic | Excellent corrosion resistance, good formability/weldability. Most versatile. | Fair/Good | Tanks, piping, food processing equipment, architectural components. |

| 316 / 316L | Austenitic | Superior corrosion resistance (Mo added), especially vs. chlorides/acids. | Fair | Marine hardware, chemical processing, medical implants, pharmaceutical equipment. |

| 17-4 PH | Precipitation Hardening | High strength (can be heat treated), good corrosion resistance, good toughness. | Good (Annealed) | Aerospace components, pump shafts, gears, high-stress structural parts. |

| 410 / 416 | Martensitic | Moderate corrosion resistance, magnetic, can be hardened/tempered. | Good (410)/Excellent (416) | Cutlery, valves, pump parts, fasteners (416 excels here). |

| 430 | Ferritic | Moderate corrosion resistance, magnetic, good formability, cost-effective. | Good | Automotive trim, appliances, decorative parts. |

Why Choose Stainless Steel for CNC Machining?

Stainless steel is a preferred material in many industries because it combines aesthetic appeal with excellent mechanical properties.

| Property | Benefit |

|---|---|

| Corrosion resistance | Ideal for medical, marine, and food-grade parts |

| High tensile strength | Suitable for structural and high-load applications |

| Heat resistance | Used in engine, aerospace, and high-temp environments |

| Aesthetic surface finishes | Excellent for visible parts and components |

| Hygienic and easy to clean | Essential for medical and food equipment |

How Does the Process Work?

From your idea to a finished part, here’s what to expect:

- Design: You provide a CAD file (or work with a provider to create one) with exact dimensions.

- Material selection: Choose a stainless steel grade based on your part’s needs (e.g., 316 for saltwater exposure).

- Machining: CNC machines (mills, lathes, etc.) cut the stainless steel using tools like drills or end mills, following the CAD design.

- Finishing: Optional steps like polishing, passivation (to boost corrosion resistance), or coating for aesthetics or extra protection.

How Much Does Stainless Steel CNC Machining Cost?

Pricing varies depending on material, part complexity, volume, and finishing requirements.

| Factor | Cost Impact |

|---|---|

| Material grade | 316 and 17-4 PH are more expensive than 303 |

| Part complexity | Intricate geometries cost more |

| Quantity | Bulk orders reduce unit price |

| Tolerance and finish | Tighter tolerances and mirror finishes add cost |

On average, simple stainless steel CNC parts range from $10 to $100+ per piece.

How to Choose the Right CNC Machining Partner

When selecting a stainless steel CNC machining service, look for:

- Experience with stainless steel

- Certifications (ISO 9001, AS9100, etc.)

- Material traceability

- Advanced CNC equipment

- Good communication and DFM support

- Positive customer reviews or case studies

Benefits for Your Project

- Precision: Parts meet tight tolerances (often as low as ±0.001 inches), critical for fitting with other components.

- Consistency: CNC machines produce identical parts, even in large batches—no “one-off” variations.

- Flexibility: Handles simple shapes (bolts) or complex geometries (intricate medical tools) with ease.

- Cost-effectiveness: For small to medium batches, CNC avoids the high setup costs of mold-based manufacturing.

Final Thoughts

Successfully machining stainless steel requires deep material knowledge, experience, and the right technology. To achieve precision, quality, and cost-effectiveness, it’s important to understand the challenges. You need to select the right grade and use optimized machining strategies.

At Topfast, we specialize in solving the complexities of stainless steel CNC machining. Our skilled craftsmen, state-of-the-art equipment, and unwavering focus on quality ensure your critical components meet the highest standards of performance and durability. Ready to discuss your next stainless steel project? Or if you have further questions, contact us!

Frequently Asked Questions (FAQs)

Q1: What is the best stainless steel for CNC machining?

A: 303 is easiest to machine, but 304 and 316 offer better corrosion resistance. 17-4 PH is ideal for strength.

Q2: Can stainless steel be CNC machined with tight tolerances?

A: Yes, experienced shops can achieve tolerances as tight as ±0.005 mm.

Q3: Is stainless steel more expensive to machine than aluminum?

A: Yes, due to tool wear, longer machining time, and harder material properties.

Q4: How long does CNC machining stainless steel take?

A: Lead times can vary from 2–10 days for prototypes, longer for large orders or complex parts.

Q5: Do CNC machining services provide material certification?

A: Reputable services often provide mill certificates or material traceability upon request.