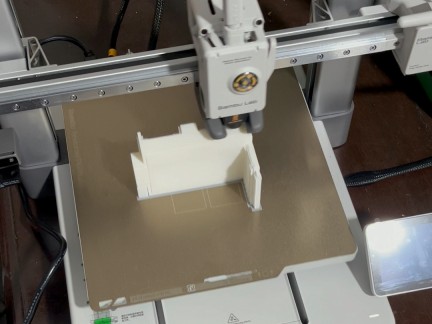

3D printing, or additive manufacturing, changes digital designs into real objects. It works by adding material layer by layer. 3D printing is different from CNC machining. Instead of removing material from a solid block, it adds material only where needed. This allows for amazing design freedom and cuts down on waste.

How Does 3D Printing Work?

At its core, 3D printing turns a digital 3D model into a real object in four simple steps:

- Design a 3D model: Use software (e.g., Blender, Tinkercad) to create or download a 3D design file (STL or OBJ format).

- Slice the model: Special software (slicers like Cura) splits the 3D model into thin layers (usually 0.1–0.3mm thick) and tells the printer how to build each layer.

- Print layer by layer: The 3D printer follows the sliced instructions, depositing or solidifying material one layer at a time to build the object from the bottom up.

- Post-process (if needed): Remove supports, sand, paint, or cure

Core 3D Printing Processes

- Fused Deposition Modeling (FDM): Melts thermoplastic filament through a heated nozzle

- Stereolithography (SLA): Uses UV lasers to cure liquid resin into solid layers

- Selective Laser Sintering (SLS): Fuses polymer powders with lasers – ideal for functional parts 2

- Metal Printing (LPBF/DED): Laser powder bed fusion (e.g., Inconel parts) and directed energy deposition (e.g., wire-laser systems) 510

The following is a comparison table:

| Technology | How It Works | Materials Used | Best For |

| FDM (Fused Deposition Modeling) | Melts plastic filament and extrudes it through a nozzle. | PLA, ABS, PETG | Prototypes, toys, basic parts |

| SLA (Stereolithography) | Uses UV light to harden liquid resin layer by layer. | Photopolymer resin | Detailed parts, jewelry, dental models |

| SLS (Selective Laser Sintering) | A laser fuses powdered material (e.g., nylon). | Nylon, metal powders | Strong, functional parts, aerospace components |

Where is 3D Printing Used?

3D printing isn’t just for hobbyists. It’s revolutionizing industries:

- Manufacturing: Prototyping new products (e.g., phone cases, machine parts) quickly, reducing development time by up to 70% compared to traditional methods.

- Healthcare: Creating custom prosthetics, dental implants, and even 3D-printed surgical guides that fit a patient’s unique anatomy.

- Aerospace: Building lightweight, complex parts for rockets and planes. For example, NASA uses 3D printing to make rocket components, cutting weight by 30%.

Consumer Goods: From custom jewelry to personalized home decor, 3D printing lets brands offer one-of-a-kind products.

Advantages of 3D printing driving adoption

- Unmatched Design Freedom: Create hollow structures, internal channels, and organic shapes impossible with CNC 2

- Rapid Prototyping: Turn CAD models into functional parts in hours – accelerating R&D cycles by 70-90% 6

- Mass Customization: Economically produce patient-specific implants or custom jigs 9

- Supply Chain Resilience: Print spare parts on-demand (e.g., aerospace firms cut lead times from 200 days to weeks) 6

- Resource Efficiency: Uses only needed material, unlike subtractive methods that cut away excess.

3D printing also has its drawbacks:

- Speed for large production: Not as fast as mass manufacturing for big batches.

- Material limits: Some printers only work with specific plastics or metals.

- Cost: High-end industrial printers can be expensive (though consumer models are affordable).

FAQs About 3D Printing

Q: Can 3D printing replace CNC machining?

A:Not entirely – they complement each other. Use 3D printing for complex geometries/prototypes, CNC for high-precision, volume production 47.

Q: How long does 3D printing take?

A:A small part (e.g., a keychain) takes 30 minutes to 2 hours. Larger, complex objects (e.g., a prosthetic leg) can take 10+ hours.

Q: What materials can be 3D printed?

A: Plastics (PLA, ABS), metals (titanium, stainless steel), resins, ceramics, and even food (like chocolate) or biocompatible materials for medical use.

Q: Is 3D printing better than CNC machining?

A: Not necessarily. 3D printing excels at complex shapes and customization; CNC machining is better for high-precision, strong parts in large batches.

Q: Is hybrid manufacturing feasible?

A: Absolutely. Many shops 3D-print near-net shapes then CNC machine critical features – combining design freedom with precision 10.