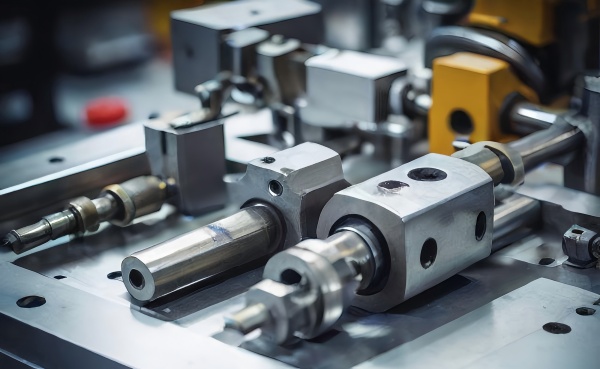

If you’ve ever needed a custom screw, shaft, or flange, chances are it was made using CNC turning. This process is the backbone of precision manufacturing for cylindrical parts. But what exactly is it, and why does it matter for your projects? Let’s break it down.

CNC Turning Explained Simply

CNC turning uses computerized controls to rotate a workpiece (like metal or plastic) while a cutting tool shapes it. Unlike milling (where the tool rotates), in turning, the workpiece spins, and the tool moves linearly to shave off material. Think of it like a high-tech lathe: raw material spins, and tools carve precise diameters, grooves, or threads.

Types of CNC Turning Operations

CNC turning can create a variety of features, including:

- Straight Turning: Creates a smooth, cylindrical surface.

- Taper Turning: Shapes the workpiece to a cone-like taper.

- Threading: Cuts screw threads (internal or external) for bolts or nuts.

- Facing: Trims the end of the workpiece to make it flat and square.

- Contour Turning: Shapes complex curves or irregular profiles (e.g., for custom shafts).

How Does CNC Turning Work?

The process boils down to a few key steps:

- Design & Programming: A 3D model of the part is created using CAD (Computer-Aided Design) software. This model is then converted into G-code (a programming language for machines) via CAM (Computer-Aided Manufacturing) software, which tells the lathe exactly how to move.

- Set-Up: The raw material (like a metal bar or plastic rod) is clamped into the lathe’s chuck, a device that holds it securely as it spins.

- Machining: The lathe spins the workpiece at high speeds (up to thousands of RPM). The cutting tool, mounted on a movable carriage, feeds into the rotating material, trimming away excess to match the programmed design.

- Finishing: After the main shaping, secondary operations (like polishing or threading) may be added to meet tight tolerances or surface finish requirements.

Advantages of CNC Turning

High Precision CNC turning can achieve tolerances as tight as ±0.005 mm, which is crucial for components like shafts and bushings.

Fast Production Ideal for both prototyping and mass production, CNC lathes are faster than manual machining or 3D printing for certain geometries.

Cost-Effective for Round Parts Compared to milling, turning is usually more efficient and economical for cylindrical shapes.

Materials Used in CNC Turning

CNC turning works with a wide range of materials, including:

- Metals: Aluminum, steel, brass, copper, titanium, and stainless steel.

- Plastics: Acrylic, nylon, PVC, and Delrin (ideal for low-friction parts).

- Exotics: Inconel (for high-heat applications) or magnesium (lightweight parts).

The choice depends on the part’s use (e.g., strength for automotive parts, corrosion resistance for medical tools).

CNC Turning vs. CNC Milling – What’s the Difference?

While both are CNC machining processes, they serve different geometries:

| Feature | CNC Turning | CNC Milling |

|---|---|---|

| Motion Type | Rotating workpiece | Rotating tool |

| Suitable Geometry | Cylindrical or round parts | Flat or complex 3D parts |

| Typical Machines | CNC lathe, turning center | CNC milling machine |

| Common Parts Made | Shafts, pins, bushings | Brackets, enclosures, molds |

If your part is round, symmetric, or has threads, CNC turning is likely the better choice.

When Should You Choose CNC Turning?

Use CNC Turning When:

- Your part is round or symmetrical.

- You need high precision and repeatability.

- You’re working with metal or plastic rods.

- You need fast turnaround for cylindrical parts.

- Threading or grooving is required.

Wrapping Up

CNC turning transforms raw material into precision cylindrical parts with unbeatable speed and accuracy. Whether you’re prototyping or scaling production, it’s a smart choice for shafts, connectors, and rotational components.

Need CNC-turned parts? Topfast offers ISO-certified turning services in aluminum, steel, and engineering plastics. Contact us for a quote today!

Frequently Asked Questions (FAQ)

Q1: What’s the difference between CNC turning and a manual lathe?

A: CNC turning is automated and programmable, ensuring higher precision and repeatability. Manual lathes require hands-on operation and are less consistent.

Q2: Can CNC turning create square shapes?

A: Not directly. Turning is ideal for round profiles. Add milling (via live tooling) for flats or slots.

Q3: What tolerances can CNC turning achieve?

A: Typically ±0.005″ (0.127mm), down to ±0.001″ (0.025mm) for high-precision setups.

Q4: Is CNC turning cost-effective for prototypes?

A: Yes! It’s fast for small batches and avoids expensive molds.

Q5: How much does CNC turning cost?

A: Prices vary based on material, size, complexity, and quantity. Generally, the cost per unit drops with higher volumes.