Technology is changing fast. Two key manufacturing methods—CNC machining and 3D printing—are reshaping how we design, prototype, and make parts. But what exactly is the difference between them? If you’re a designer, engineer, or business owner, this guide will help you choose the best method for your project. It clearly explains the differences.

Understanding CNC Machining

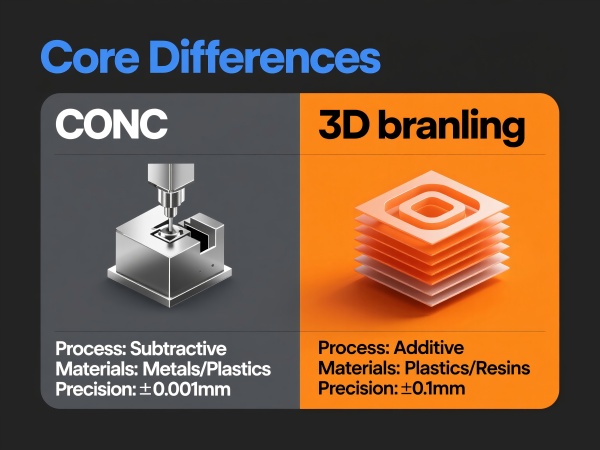

CNC (Computer Numerical Control) machining is a subtractive manufacturing process. It uses computer-controlled tools to cut and shape material blocks (known as workpieces) into the desired form. Common tools include mills, lathes, routers, and grinders.

How CNC Works:

- A CAD (Computer-Aided Design) file is created.

- CAM software translates the CAD file into machine code (G-code).

- The CNC machine executes the code to remove material from a solid block.

Understanding 3D Printing

3D printing, also known as additive manufacturing, builds objects layer by layer using materials like plastics, resins, or even metal powders. Instead of cutting material away, 3D printers add material only where needed.

How 3D Printing Works:

- A 3D model is prepared using slicing software.

- The printer deposits material one layer at a time.

- The final object is built from the ground up.

Key Differences Between CNC Machining and 3D Printing

| Feature | CNC Machining | 3D Printing |

|---|---|---|

| Process Type | Subtractive | Additive |

| Material Use | Cuts from solid blocks (more waste) | Adds only necessary material (less waste) |

| Material Range | Metals, plastics, wood, composites | Plastics, resins, metals (limited range) |

| Surface Finish | Smooth, high-quality finish | Often rough; may require post-processing |

| Accuracy & Tolerance | High precision (±0.01 mm or better) | Medium to low precision |

| Production Speed | Fast for large volumes | Slower, especially for large parts |

| Complex Geometry | Limited by tool access | Excellent for complex and internal shapes |

| Setup & Operation | Skilled operators required | Often simpler, more user-friendly |

| Cost (Low-Volume) | Higher due to setup and tooling | Lower for prototyping or custom items |

| Cost (Mass Production) | Cost-effective per unit at high volumes | Not ideal for mass production |

Which One Should You Choose?

Your choice depends on what you need:

✅ Choose CNC Machining if:

- You require high precision and tight tolerances

- Your part needs to be made from strong metals or high-performance plastics

- You want a professional-grade finish with minimal post-processing

- You’re producing medium to high volumes

- Mechanical performance and durabaility are key

✅ Choose 3D Printing if:

- You need a quick prototype or custom part

- The design has complex internal structures

- You want to reduce material waste

- You’re working on small-batch or single-unit production

- Material choice (especially for non-metal parts) suits your application

Real-World Application Comparison

| Industry | CNC Machining Example | 3D Printing Example |

|---|---|---|

| Aerospace | Aluminum engine brackets | Lightweight cabin interior components |

| Automotive | Gear shafts, engine blocks | Prototyped dashboards, clips |

| Medical Devices | Surgical tools, implants (metal) | Customized prosthetics, dental models |

| Consumer Goods | Precision parts for appliances | Prototypes for product testing |

| Architecture | Metal fixtures | Architectural models |

Environmental Considerations

- CNC generates waste through material removal. However, recyclable scrap materials (especially metals) can be reused.

- 3D Printing minimizes waste but may use non-recyclable polymers. Some processes also release fumes or VOCs.

Conclusion

Knowing these key differences and trade-offs helps you choose the best manufacturing technology for your next project. This way, you can achieve a good balance of cost, speed, performance, and quality. If you have a specific part in mind, consulting with a manufacturing expert (like us!) is always recommended!