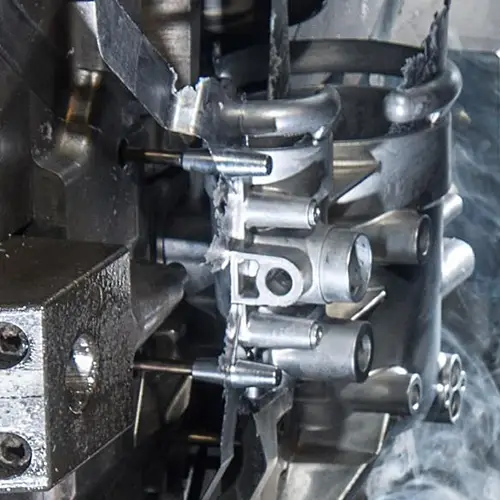

Die Casting

- Tolerance down to ± 0.004'' (0.1 mm)

- Get a quick quote within 4 hours

- Complete and strict QC system

- ISO 9001:2015 certified manufacturing partner

Process of Die Casting

Topfast works with its partners to provide high quality, made-to-order components using the latest die casting technology. Typical tolerances are typically in the range of ±0.0762 mm to ±0.127 mm for aluminum and zinc materials, depending on customer specifications.

Hot chamber die casting, also known as gooseneck die casting, is the most widely used die casting process. In this process, the chambers of the injection mechanism are submerged in molten metal, and a “gooseneck” metal supply structure introduces molten metal into the mold cavity.

The purpose of using cold chamber die casting is usually to reduce machine wear. The liquefied metal is loaded directly into the injection mechanism, thus eliminating the need to submerge the injection mechanism in molten metal.