Injection Molding

- Employs high-precision methods

- Quick lead times

- Competitive Pricing

- Skilled injection molding operator with rich experience

- Comprehensive Support throughout the entire project

- Get a quick quote within 4 hours

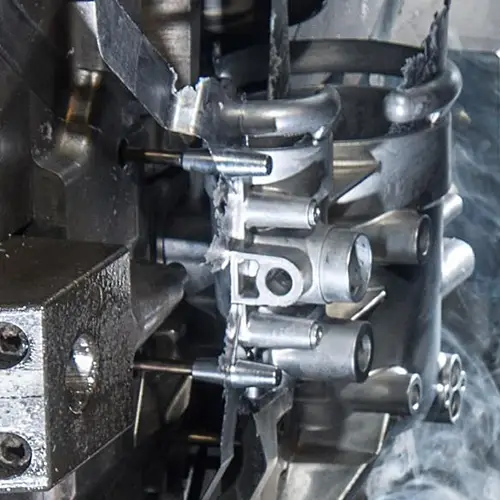

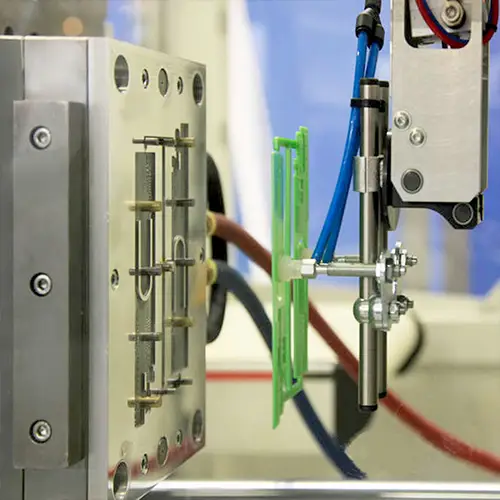

Injection Moulding Services

Injection moulding is the most cost-effective way to make a plastic part at scale and offers consistent quality for low-to-high volume manufacturing. Xometry offers a vast number of rigid plastics and resins that meet required structural and cosmetic characteristics. Beyond materials, injection moulded parts can have custom finishing, polishes, or surface textures. Xometry offers both high-precision tool manufacturing and injection moulding services.

Topfast Injection Moulding Mould Classes

| Mould class | Cycles | Production level | Mould base | Minimum hardness (BHN) | Description |

|---|---|---|---|---|---|

| 101 | >1 million | High | Heat-treated stainless steel | 280 | Fast cycle times and very high production rate |

| 102 | <1 million | Medium-High | Heat-treated tool steel | 280 | Good for parts with abrasive materials and tight tolerances |

| 103 | <50,000 | Medium | P20 Steel | 165 | Widely used for low to medium production parts |

| 104 | <10,000 | Low | Mild steel, aluminum, or alloys | <165 | Good for limited-production parts especially with non-abrasive materials |

| 105 | <500 | Very low | Soft aluminum, epoxy, cast materials | <165 | Mostly used for prototype production |

Advantages of Injection Moulding with Topfast

Rapid Turnaround

We offer fast mould lead times: in as fast as 10 business days for rapid tooling and up to 20 days for production tooling.

Serial Production

Ideal for the production starting from 100 parts.

Precision

Xometry offers tight tolerance options in accordance with ISO 16742, up to ±0,07 mm depending on the precision of the mould and size of the parts.

Tooling

Single, multi-cavity, and family mould options.

Material Selection

Vast materials selection allows you to get the desired strength and surface quality.

Quality Control

Our QA department performs strong quality assurance.

Injection Moulding Materials

- ABS | Acrylonitrile Butadiene Styrene

- ASA | Acrylonitrile Styrene Acrylate

- CA | Cellulose Acetate

- COPO | Copolyester

- HDPE | High-Density Polyethylene

- LCP | Liquid Crystal Polymer

- LDPE | Low-Density Polyethylene

- PA 6 | Polyamide 6, Nylon 6

- PA 6/6 | Polyamide 6/6, Nylon 6/6

- PARA | Polyacryl Amide

- PBT | Polybutylene Terephthalate, Valox

- PBT-PET | Polybutylene Terephthalate-Polyethylene Terephthalate

- PC | Polycarbonate

- PC-ABS | Polycarbonate-Acrylonitrile Butadiene Styrene

- PC-PBT | Polycarbonate-Polybutylene Terephthalate, Xenoy

- PC-PET | Polycarbonate-Polyethylene Terephthalate

- PCT | Polycyclohexylenedimethylene Terephthalate

- PE | Polyethylene

- PE-PP | Polyethylene-Polypropylene

- PE-PS | Polyethylene-Polystyrene

- PEBA | Polyether Block Amide

- PEEK | Polyether Ether Ketone

- PEI | Polyetherimide, Ultem

- PES | Polyether Sulfone

- PET | Polyethylene Terephthalate, Rynite

- PLA | Polylactic Acid

- PMMA | Polymethyl Methacrylate, Acrylic

- POM | Acetal Polyoxymethylene, Delrin

- PP | Polypropylene

- PPA | Polyphthalamide

- PPS | Polyphenylene Sulfide, Ryton

- PS | Polystyrene

- PS-PPE | Polystyrene-Polyphenyl Ethers, Noryl

- PSU | Polysulfone, Udel

- PVC | Polyvinyl Chloride (Shore D)

- PVDF | Polyvinylidene Fluoride

- SAN | Styrene Acrylonitrile

- TPO | Thermoplastic Polyolefin

- TPU | Thermoplastic Polyurethane (Shore D)

- EPDM | Ethylene Propylene Diene Monomer Rubber, Viton

- MPR | Melt Processable Rubber

- POE | Polyolefin Elastomer

- PVC | Polyvinyl Chloride (Shore A)

- TPE | Thermoplastic Elastomer, Santoprene

- TPU | Thermoplastic Polyurethane (Shore A)

- TPV | Thermoplastics Elastomer, Vulcanized Rubber

- LSR | Liquid Silicone Rubber