With the development of the automobile industry, the requirements for auto parts processing are getting higher and higher. Although traditional manual processing can meet certain production needs, there are big problems in efficiency, precision and quality. The emergence of numerical control technology has greatly improved these problems and brought many advantages to the processing of auto parts.

Overview of CNC machining technology

Numerical control technology is a method to control workpiece cutting motion by automatic equipment using pre-programmed control program. Its advantage is that it can greatly shorten the production cycle, improve production efficiency, improve product accuracy, ensure the stable quality of products, and can greatly reduce labor costs.

Numerical control technology is divided into two types: numerical control machine tool and numerical control machining center. CNC machine tools usually complete the processing of parts separately, and its control system is mainly programmed by G code; The CNC machining center can complete a variety of parts processing processes, is an efficient, flexible, programmable automatic processing equipment, its programming mainly uses CAM or CAD manufacturing software.

Application of numerical control technology in auto parts processing

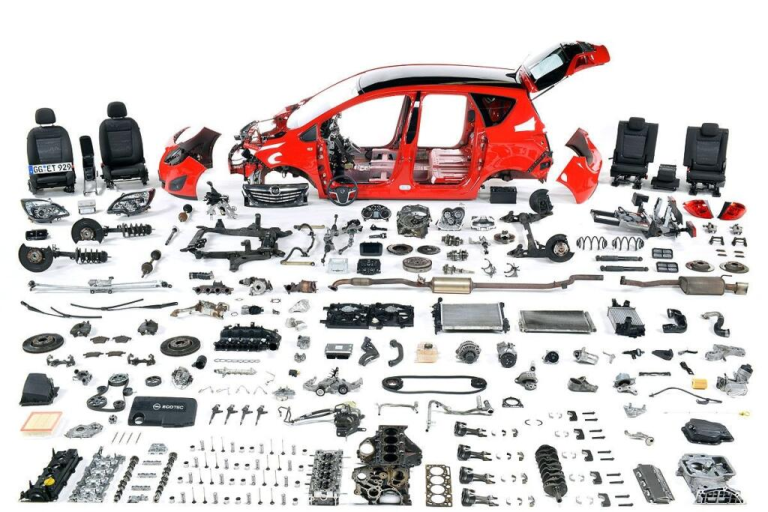

Numerical control technology is widely used in auto parts processing. Taking automotive engines as an example, CNC technology can process important components such as cylinder body and crankshaft with high precision, so as to ensure the stable operation of the engine and reduce emissions. The following is the application of numerical control technology in automotive parts processing:

Parts processing

CNC technology can be used for high-precision machining of automotive parts, such as hubs, brake discs, pistons, valves, crankshafts, camshafts and so on. In high-speed machining, high-precision machining and multi-functional machining, CNC tool machine has irreplaceable advantages.

Parts inspection

High-precision parts processing requires that the accuracy of the shape and size of the parts be controlled within a small tolerance range, which requires accurate detection of the parts. The CNC inspection robot can independently detect the appearance accuracy of multi-variety and small-batch parts, and can directly feed the test data to the processing equipment, so as to realize the organic combination of automatic detection and processing.

Part design

The design stage before the part processing is very important for the part processing. Numerical control technology can efficiently design parts through CAD and other software, and automatically generate manufacturing process data for process planning and manufacturing.

Manufacturing process planning

The use of numerical control technology does not need to worry about whether certain processes will be missed in the processing process, or whether the sequence of processes is reasonable. Manufacturing process planning can be programmed by using CAM software, which directly transfers the program to CNC machine tools and CNC machining centers for processing.

Processing quality monitoring and control

Numerical control technology can achieve online monitoring and control, (real-time monitoring of temperature, vibration, cutting force and other parameters), through the feedback to the processing program, accurate control of the relative motion between the tool, the workpiece and the machine tool, so as to improve the processing quality and enhance production efficiency.

The advantages of numerical control technology in auto parts processing

Improve production efficiency

CNC machining equipment has the advantages of high speed, high precision, high efficiency, etc., which greatly shortens the production cycle, improves the production efficiency, and makes the processing industry more efficient.

Ensure processing quality

Through on-line monitoring and control, CNC technology realizes real-time dynamic control of the workpiece processing process, reduces manual errors, ensures the precision of parts processing, and greatly improves the processing quality.

Improve production flexibility

CNC equipment is flexible and changeable, not only can complete the processing of parts, but also can complete the processing of a variety of parts at the same time, with a wide range of adaptability, greatly increasing the flexibility of the planning and layout of the production line.

Reduce labor costs

Compared with the traditional manual processing method, numerical control technology can save a lot of labor costs, especially for flexible, unstable demand manufacturing systems, numerical control technology has a more obvious advantage.

In short, the wide application of numerical control technology has had a significant impact on the quality, efficiency and cost of automotive parts processing. With the continuous innovation and development of technology, the application prospect of numerical control technology in the automotive industry is bound to be broader.

Explore Cutting-Edge Precision Metal Solutions with TOPFAST CNC

Guangzhou Topfast Technology Co., Ltd is a leading manufacturer specializing in rapid prototyping & on-demand production.

With state-of-the-art machines operated by engineers who are unmatched in skills and experience, we offer CNC machining, injection molding, vacuum casting, die casting, 3D printing, sheet metal fabrication, and more.

We are certified in ISO9001, ISO16949, and ISO13485, reflecting our commitment to innovation and improvement.

Our capabilities ensure customers bring ideas to life in no time, providing comprehensive one-stop solutions from prototyping to mass production. Flagship always delivers quality custom parts with precision and efficiency while saving your time, cost, and effort.